This is a nice alert!

Analysing business/process performance using Production System Methodologies enabling focused understanding of business/process constraints. Define and deliver recommendations to support constraints.

Understanding your current vision and strategy then together develop and plan short- and medium-term goals

Understanding your current vision and strategy then together develop and plan short- and medium-term goals

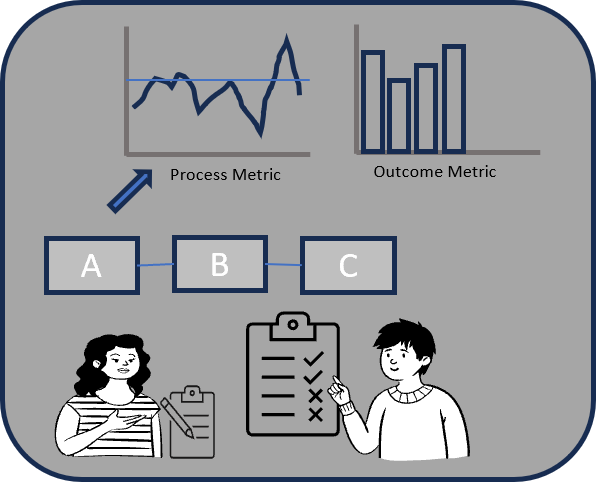

Develop KPI’s to enable the business to understand process performance unlocking improvement and delivery

Develop KPI’s to enable the business to understand process performance unlocking improvement and delivery

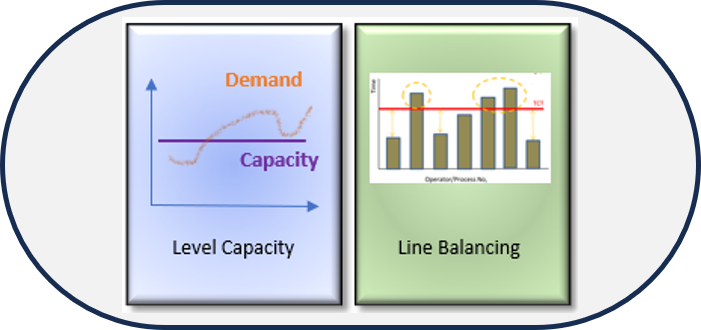

Understanding and development of businesses Capacity Planning Process enabling the vision of the required production capacity to meet changing demands

Understanding and development of businesses Capacity Planning Process enabling the vision of the required production capacity to meet changing demands

Understanding your Business skill and training capability, develop training needs to unlock teams potential

Understanding your Business skill and training capability, develop training needs to unlock teams potential

Review and identify your Business Challenges and constraints

Structured data gathering using process observation (Gemba)

Develop current condition process maps to support data gathered

Set out a structured road map to address the Business challenges and constraints

I have spent 30 years in the Automotive Industry working for two of the largest OEM’s as a maintenance and then operations leader. I have also held Senior Operations roles with two first tier suppliers.

I then worked for 14 years in the Aerospace Industry where I held Operations & Business Improvement Management roles.

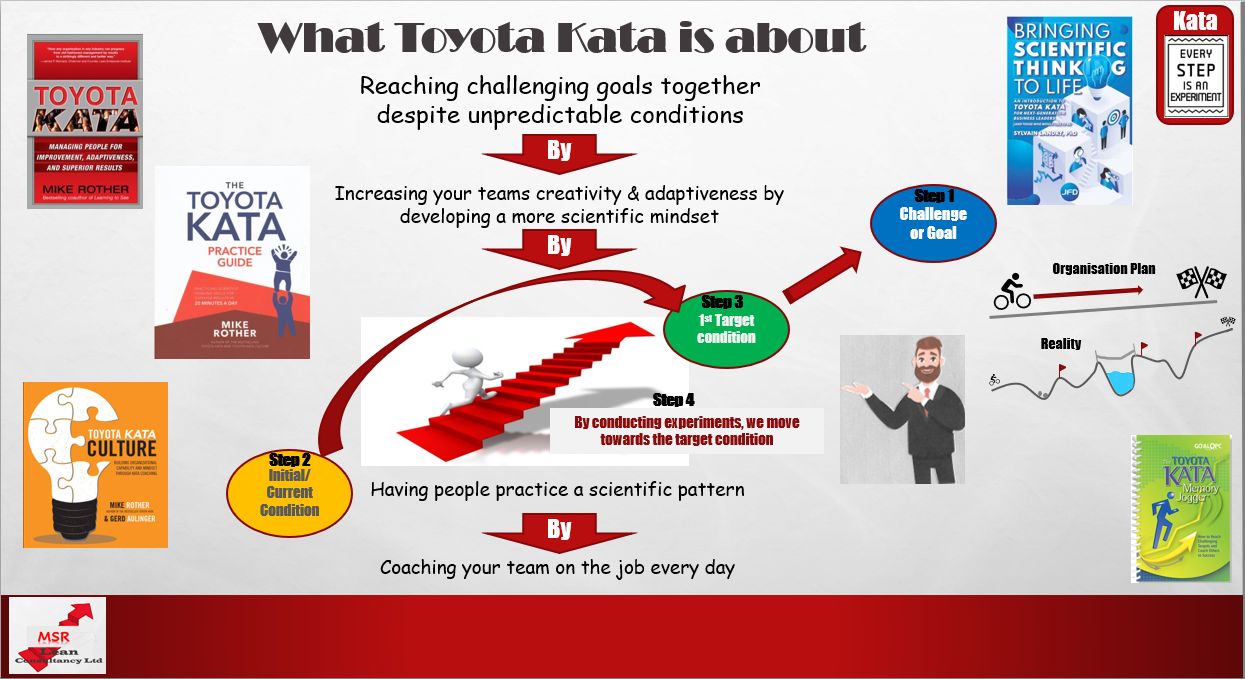

Last year I set up my own business as a Lean Consultant, helping clients understand their Business Constraints, enable employees (Teams or leadership) unlock their potential and become self-sufficient, empowering them to understand, identify and develop solutions through scientific thinking. Which enables Business growth.

Through my career I have developed my skills and knowledge which has enabled me to coach individuals, teams and leaders in Lean thinking and leadership behaviors. I am a certified Lean/6 sigma Black Belt and Toyota Kata coach which has helped me focus my scientific way of thinking.

Recently I Project Managed multiple Supply Chain & Logistics projects as an Associate Lean Consultant for North Star Projects serving clients in the UK and overseas.